Above we called the buyers-up the biggest of the industrialists. From the ordinary Narodnik viewpoint, this is heresy. It is customary to depict our buyers-up as individuals who take no part in production, who are extraneous and alien to industry itself, and depend “solely” on exchange.

This is not the place to dwell in detail on the theoretical fallacies contained in this view, which is based on a failure to understand the general and principal groundwork, foundation, or background of present-day industry (handicraft industry included)—namely, commodity economy, of which merchant capital is an essential component, and not a casual and incidental adjunct. Here we must stick to the facts and figures of the handicraft census, and our task will now be to examine and analyse the data on buyers-up. A circumstance favouring this examination is the fact that handicraftsmen who work for buyers-up have been put into a separate sub-group (the third). But this advantage is outweighed by the great number of omissions and uninvestigated factors, which rather seriously complicates our inquiry. No data are available on the number of buyers-up, on large buyers-up and small, on their ties with the well-to-do handicraftsmen (ties of origin, ties between the commercial operations of the buyer-up and production in his workshop, etc.), on the business of the buyer-up. The Narodnik prejudice of treating the buyer-up as extraneous prevented most investigators of handicraft industry from examining business done by buyers-up, although this is obviously a prime and principal question for the economist. A careful and detailed study should be made of the business methods of the buyer up, how his capital is built up, how this capital operates in the purchase of raw material and the sale of the product, what are the conditions (social and economic) in which capital operates in these spheres, what expenses he incurs in organising purchases and sales, how these expenses vary according to the amount of merchant capital and the volume of purchases and sales, and what conditions sometimes induce the buyer-up to process the raw material partly in his own workshops and then to give out the semi-finished product to domestic workers for further processing (the final finishing process sometimes being done by the buyer up himself), and sometimes to sell the raw material to small industrialists, in order, later, to buy their wares in the market. A comparison should be made between the cost of production of an article turned out by a small handicraftsman, by a large producer in a workshop where several wage-workers are employed, and by a buyer-up who gives out material to be worked up by domestic workers. The unit of investigation should be each enterprise, that is, each separate buyer-up, and it is necessary to determine the amount of his turnover, the number of persons working for him in his workshop or workshops, or in their own homes, the number of workers he employs to acquire raw materials, to store them and the finished product, and to sell the latter. A comparison should be made between the technique of production (number and quality of implements and fixtures, division of labour, etc.) used by the small master, the workshop owner who employs wage-workers, and by the buyer-up. Only such an economic investigation can give an exact scientific answer to the questions: what is a buyer-up, what is his significance in the economic process and in the historical development of the forms of industry under commodity production. The absence of such information in the conclusions of the house-to house census, which made a detailed study of all these questions for each handicraftsman, cannot but be regarded as a serious omission. Even if it was impossible (for some reason or another) to register and investigate the business of each buyer-up, much of this information could have been drawn from the household data on handicraftsmen who work for buyers-up. Instead, we find nothing in the Sketch but hackneyed Narodnik phrases, such as: the “kulak” is “essentially alien to production itself” (p. 7)—the kulak category being extended to include both buyers-up and owners of assembly workshops, on the one hand, and usurers, on the other; “wage-labour is governed not by its technical concentration, as in the case of the factory (?), but by the monetary dependence of the handicraftsmen . . . one of the forms of kulakism” (309-10); “the source of the exploitation of labour . . . lies in the function of exchange, and not in the function of production” (101); or what we often meet with in the handicraft industries is not the “capitalisation of production,” but the “capitalisation of the process of exchange” (265). Of course, we have no intention of accusing the Sketch investigators of originality: they simply borrowed wholesale the maxims scattered so profusely in the works of, say, “our well-known” Mr. V. V.

In order to judge the true value of such phrases, we have only to remember, for example, that in one of our principal industries, textiles, the “buyer-up” was the immediate forerunner, the father, of the big manufacturer engaged in large-scale machine production. All our textile industries began with supplying yarn to be worked up by handicraftsmen at home; this, in other words, was work for the “buyer-up,” for the “kulak,” who, while possessing no workshop of his own (“was alien to production”), “merely” supplied the yarn, and took the finished goods. Our good Narodniks did not even attempt to investigate the origin of these buyers-up, their genealogical connections with the owners of small workshops, their role as organisers of the buying of raw materials and the selling of products, the role of their capital in concentrating means of production, in gathering together masses of scattered small handicraftsmen, in introducing division of labour, and in creating the elements of what is not only large-scale production but which is also becoming machine production. Our good Narodniks confined themselves to whining and complaining about this “deplorable,” “artificial,” etc., etc., phenomenon; they consoled themselves with the belief that this was not the “capitalisation” of production, but “merely” of the process of exchange, and talked sentimentally about “different paths for the fatherland.” Meanwhile these “artificial” and “unsubstantial” “kulaks” kept on following their old path, continued to concentrate capital, to “gather together” means of production and producers, to extend their purchases of raw materials, to further the division of production into separate operations (warping, weaving, dyeing, finishing, etc.) and to transform scattered, technically backward capitalist manufacture, based on hand labour and servitude, into capitalist machine industry.

An exactly similar process is now taking place in the bulk of our so-called “handicraft” industries; and the Narodniks in just the same way shun an investigation of realities as they develop, in just the same way replace a discussion of the origin of existing relations and their evolution by a discussion of what might be (if what is were not), in just the same way-console themselves with the thought that so far these are “merely” buyers-up, and in just the same way idealise and paint in rosy colours the worst forms of capitalism—worst in technical backwardness, economic imperfection, and the social and cultural conditions of the working masses.

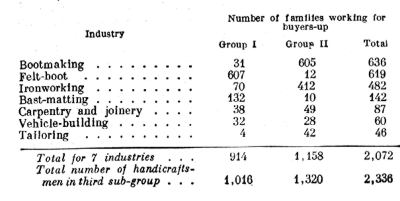

Let us turn to the data of the Perm handicraft census. Wherever necessary, we shall endeavour to make good the above-mentioned omissions by drawing upon Handicraft Industries of Perm Gubernia, etc., a book to which we have already referred. Let us first of all pick out the industries which account for the bulk of the handicraftsmen employed by buyers-up (third sub-group). For this purpose we shall have to turn to our own summary, which (as already mentioned) does not coincide with the Sketch figures.

Thus, about nine-tenths of the handicraftsmen working for buyers-up are concentrated in these seven industries. It is to these industries that we shall turn first.

Let us begin with the bootmaking industry. The overwhelming majority of the bootmakers who work for buyers up are in Kungur Uyezd, the centre of the leather industry in Perm Gubernia. A large number of handicraftsmen work for leather manufacturers: on p. 87 of the Sketch mention is made of 8 buyers-up, who have 445 establishments working for them.[1] All these buyers-up have been leather goods manufacturers “for ages,” and their names may be found in the Directory of Factories for 1890 and 1879, and in the notes to the Ministry of Finance Yearbook, Issue I for 1869.[14] The leather goods manufacturers cut out the leather and in this form distribute it to the “handicraftsmen” to be sewn. The lasting is done separately, by several families, who work to the order of the manufacturers. Generally speaking, a whole number of “handicraft” industries are connected with the leather goods factories, that is, a whole series of operations are done in the home. These include 1) dressing of hides and skins; 2) sewing of uppers; 3) gluing of leather clippings into boards for stiffeners; 4) making of screws for boots; 5) making of brads for boots; 6) last making; 7) preparation of ash for the tanneries; 8) making of “tan” (from willow bark). The scrap and waste of the leather industry are used by the felt and glue-making industries (Handicraft Industries, III, pp. 3-4, et al.). In addition to detailed division of labour (i.e., division of the production of an article into several operations performed by different persons), a commodity division of labour has arisen in this industry: each family (sometimes even each street in a handicraft village) produces one kind of foot wear. There is an amusing point we must mention—in Handicraft Industries, etc., the “Kungur leather industry” is declared to be a “typical expression of the idea of the organic connection between factory and handicraft industry to their mutual advantage” (sic !) . . . the factory entering into a correct (sic !) association with handicraft industry, with the object, in its own interests (exactly!), of developing and not reducing . . . its capacity (III, p. 3). For example, Fominsky, the manufacturer, was awarded a gold medal at the 1887 Ekaterinburg Exhibition not only for the excellent quality of his leather, but also for his “extensive operations, which furnish work for the surrounding population “ (ibid., p. 4, author’s italics). Indeed, of the 1,450 persons he employed, 1,300 were domestic workers. Of the 120 persons employed by Sartakov, another manufacturer, 100 were domestic workers, etc. Hence the Perm manufacturers vie very successfully with the Narodnik intellectuals in implanting and developing handicraft industries. . . .

The organisation of the bootmaking industry in Krasnoufimsk Uyezd (Handicraft Industries, I, pp. 148-49) is in every way analogous; the leather goods manufacturers also stitch leather boots, partly in their workshops, partly by giving the work out to domestic workers. One of the biggest of the owners of a leather and boot establishment employs about 200 regular workers.

We are now in a position to form a fairly clear idea of the economic organisation of the bootmaking and of many other allied “handicraft” industries. They are nothing but branches of large capitalist workshops (“factories,” according to the terminology used in our official statistics), performing nothing but detailed operations in the large-scale capitalist manufacture of leather goods. The entrepreneurs have organised the buying of materials on a broad scale, have set up factories for tanning the hides, and have established a whole organisation for the further processing of the leather based on the division of labour (as the technical condition) and wage-labour (as the economic condition): some of the operations (such as cutting out leather for boots) are performed in their workshops, others are performed by “handicraftsmen” who work for them in their homes, the employers determining the amount of output, the rates of payment, the kind of goods to be made, and the quantity of each kind. They have also organised the wholesale marketing of the product. Obviously, in scientific terminology this is nothing but capitalist manufacture, in part already passing into the higher form of factory industry (inasmuch as machines and machinery are used in production: the big leather factories have steam engines). To single out parts of this system of manufacture as a separate “handicraft” form of production is a patent absurdity, which only obscures the basic fact that wage-labour prevails in the leather goods production and bootmaking and that the entire trade is under the sway of big capital. Instead of comical arguments on the desirability of a “co-operative organisation of exchange” in this industry (Sketch, p 93), it would not be amiss to make a detailed study of its actual organisation, a study of the conditions which make it preferable for the manufacturers to give out work to be done in the home. The manufacturers undoubtedly find it more profitable, and we shall understand why if we bear in mind the low earnings of the handicraftsmen in general, and in particular of the handicraft agriculturists and those of the third sub-group. By giving out material to be worked up at home, the employers lower wages, economise on premises, partly on implements, and on supervision, evade the not always welcome demands made on manufacturers (they are not manufacturers but merchants!), get workers who are more scattered, disunited, and less capable of self-defence, and also unpaid taskmasters for these workers—“middle men,” “subcontractors” (as they are called in our textile industry under the system of giving out yarn to be used in the home)—in the shape of those handicraftsmen they employ and who, in their turn, employ wage-workers (it was found that the 636 families who make boots for buyers-up employ 278 wage-workers). We have already seen from the general table that these wage-workers (in the third sub-group) receive the lowest wages of all. And this is not surprising, for they are subjected to double exploitation: exploitation by their own employer who squeezes his “own little profit” out of the workers, and exploitation by the leather goods manufacturer who gives out material to the small masters. We know that these small middlemen, who are well familiar with local conditions and with the personal characteristics of the workers, are particularly prolific in inventing different forms of extortion, in practising bondage hiring, the truck system,[2] [15] etc. The excessive working hours in these workshops and “handicraftsmen’s huts” are common knowledge, and one cannot help regretting that the 1894-95 handicraft census has furnished practically no information on subjects so important for the study of our native sweating system,[3] with its host of middlemen who intensify the pressure on the workers and its utterly shameless and unrestricted exploitation.

On the organisation of the felt-boot industry (the second largest as regards the absolute number of families working for buyers-up) the Sketch, unfortunately, gives practically no information whatever. We have seen that in this industry there are handicraftsmen who employ dozens of wage-workers, but whether they give out work to be done at home, get part of the operations done outside their workshops,[4] was not made clear. Let us only note a fact mentioned by the investigators, that the sanitary conditions in the felt-boot industry are extremely unsatisfactory (Sketch, p. 119; Handicraft Industries, III, 16)—intolerable heat, excessive dust, stifling atmosphere. And this in the cottages the handicraftsmen live in! The natural result is that they are unable to stand more than fifteen years of this work and end as consumptives. I. I. Molleson, an investigator of workshop sanitary conditions, says: “The chief contingent of felt-boot makers consists of workers between the ages of 13 and 30. They are nearly all easily recognisable by their pallor, dull complexion, and their languid and sickly appearance “ (III, p. 145, author’s italics). The practical conclusion drawn by this investigator is: “It should be made incumbent on the employers to build workshops (felt-boot) of much larger size, so as to provide a specified constant volume of air per worker”; the “workshops should be designed exclusively for work, and it should be strictly forbidden to allow workers to sleep in them at night” (ibid.). In other words, the sanitary inspectors demand the building of factories for these handicraftsmen and the prohibition of work in the home. One cannot help hoping that this recommendation will be acted upon, for it would promote technical progress by eliminating a host of middlemen and would pave the way for the regulation of working hours and working conditions; in a word, it would eliminate the most crying abuses in our “people’s” industry.

Among the buyers-up in the bast-matting industry is a merchant named Butakov, who, we learn from information for 1879, had a bast-matting factory in the town of Osa, which employed 180 workers.[5] Has this manufacturer to be regarded as “alien to production itself,” just because he has found it more profitable to give out the work to be done at home? It would also be interesting to know in what way the buyers-up who have been thrown out of the list of handicraftsmen differ from those “handicraftsmen” who, having no family workers, “purchase bast and give it out to craftsmen to make into matting and sacks on their own looms” (Sketch, 152)—a striking illustration of the confusion into which the investigators have been led by Narodnik prejudices. The sanitary conditions in this industry will also not bear criticism—overcrowding, filth, dust, damp, foul smells and long working hours (12 to 15 a day), all of which turns the centres of the industry into veritable “hotbeds of famine typhus,”[6] of which, in fact, there have been frequent outbreaks.

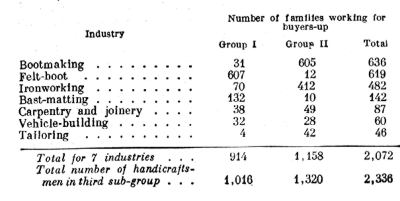

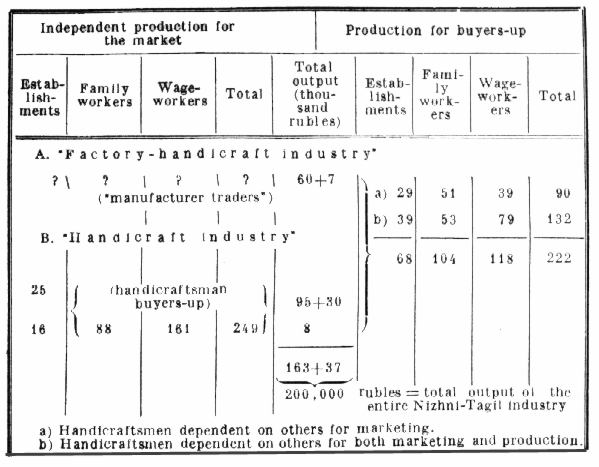

On the organisation of work for buyers-up in the ironworking industry, we again learn nothing from the Sketch and are again obliged to turn to Handicraft Industries, etc., which contains a very interesting description of this industry in Nizhni-Tagil. The manufacture of trays and other articles is divided among several establishments: forging, tinning, and decorating. Some of the handicraft masters have establishments of all these kinds, and are consequently manufacturers of the pure type. Others perform one of the operations in their own workshops and then give out the articles to handicraftsmen for tinning and decorating in their homes. Here, consequently, the uniformity of the economic organisation of the industry—both when the work is given out to be done in the home and when several detail workshops belong to one master—stands out very clearly. The handicraftsmen who act as buyers-up, giving out work to be done at home, are among the biggest masters (of whom there are 25) who have organised the most profitable purchase of raw material and the marketing of the product on a large scale; these twenty-five handicraftsmen (and they alone) take their goods to the fair or have their own shops. In addition to them, the big “manufacturer traders” are also buyers-up; they exhibited their wares at the Factory Department of the Ekaterinburg Exhibition. The author of the book classes them under “factory-handicraft (sic !) industry” (Handicraft Industries, I, pp. 98-99). Thus, on the whole, we get a very typical picture of capitalist manufacture, interwoven in the most diverse and fantastic ways with small establishments. In order to demonstrate clearly how little the division of industrialists into “handicraftsmen” and “manufacturers,” into producers and “buyers-up,” helps us to understand these complex relations, let us take the figures given in this book and show the economic relations in the industry in a table:

And now we shall be told that the buyers-up, like the usurers, are “alien to production itself,” that their domination merely implies the “capitalisation of the process of exchange,” and not the “capitalisation of production”!

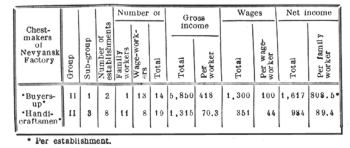

Another highly typical instance of capitalist manufacture is the chest-making industry (Sketch, pp. 334-39; Handicraft Industries, I, pp. 31-40). It is organised as follows: a few big proprietors who own workshops employing wage-workers purchase the materials, partly manufacture the goods in their own workshops, but mainly give out material to small detailed workshops, subsequently assembling the various parts of the chest in their own workshops and sending the finished article to market. Division of labour—the typical condition and technical basis of manufacture—is widely employed in production: the making of a complete chest is divided into ten or twelve detailed operations each performed by different handicraftsmen. Thus, the organisation of the industry consists in combining detail workers (Theilarbeiter, as they are called in Das Kapital) under the command of capital. Why capital prefers to give out work to be done at home rather than employ wage-workers in a workshop is made quite clear by the data provided in the 1894-95 handicraft census on the establishments of the Nevyansk Factory, Ekaterinburg Uyezd (one of the centres of the industry), where, side by side with assembly workshops, we also meet with detail handicraftsmen. Hence a comparison between the two is quite possible. Here are comparative figures given in a table (on p. 173 of the tables):

TRAPPED INSIDE JPEG: 808.5[7]

Before examining this table, we must say that if we had taken the data for the entire first and third sub-groups (Sketch, p. 335) and not for the Nevyansk Factory alone, the conclusions would have been the same. The gross income in the two sub-groups obviously cannot be compared, for the same material passes through the hands of various detail workers and through the assembly workshops. But the data for incomes and wages are characteristic. We find that the wages of hired workers in the assembly workshops are higher than the incomes of the dependent handicraftsmen (100 rubles and 89 rubles respectively), notwithstanding the fact that the latter exploit wage-workers in their turn. But the wages of these latter are less than half those of the workers in the assembly workshops. Why, then, should our employers not prefer “handicraft” industry to factory industry, when the former yields them such substantial “advantages”! We find a fully analogous organisation of production for the buyers-up in the vehicle-building industry (Sketch, p. 308, et. seq.; Handicraft Industries, I, p. 42, et. seq.)—the same assembly workshops, whose owners are “buyers-up” (and work-distributors, work-givers) in relation to the handicraftsmen who make the parts, and the earnings of the wage-worker in the workshop are again higher than the income of the dependent handicraftsman (not to mention his wage-worker). These higher wages are recorded for both agriculturists (Group I) and non-agriculturists (Group II). In the cabinet-making industry, the buyers-up are the furniture shops in the city of Perm (Sketch, 133; Handicraft Industries, II, 11) that supply the handicraftsmen with models when placing orders, and in this way, incidentally, have “gradually improved the technique of production.”

In the tailoring trade, the ready-made clothing shops in Perm and Ekaterinburg give out material to be made up by handicraftsmen. As we know, an exactly similar organisation of the tailoring and dressmaking industry also exists in other capitalist countries, in Western Europe and America. The difference between the “capitalist” West and Russia, with her “people’s industry,” is that this state of affairs is called the Schwitz-system[8] in the West and means are sought to combat this worst of all systems of exploitation; the German tailors, for example, demand that the masters should build factories (that is, are “artificially implanting capitalism,” as the Russian Narodnik would put it)—whereas in our country this “sweating system” is benignly called “handicraft industry” and its superiority to capitalism is argued and discussed.

We have now examined all the industries in which the vast majority of handicraftsmen employed by buyers-up are engaged. What are the results of our review. We have become convinced of the absolute unsoundness of the Narodnik contention that the buyers-up, and even the assembly workshop masters, are mere usurers, elements alien to production, and so on. Despite the above-mentioned inadequacy of the Sketch data, despite the absence in the census programme of questions about the business conducted by the buyers-up, we have succeeded in establishing, for most of the industries, intimate ties between the buyers-up and production—even their direct participation in production, “participation” as owners of shops which employ wage-workers. Nothing could be more absurd than the opinion that working for buyers-up is merely the result of some abuse, of some accident, of some “capitalisation of the process of exchange” and not of production. The contrary is true: working for a buyer-up is a special form of production, a special organisation of economic relations in production—an organisation which has directly sprung from small commodity production (“petty people’s production,” as it is customary to call it in our lofty literature), and which to this day is connected with it by a thousand threads; for it is the most prosperous petty masters, the most go-ahead “handicraftsmen,” who lay the basis for this system by extending their operations through supplying work to domestic workers. Work for buyers-up is directly associated with the capitalist workshop employing wage-workers, and often just constitutes an extension of it or one of its departments; it is simply an adjunct of the factory, understanding this latter expression in the generally accepted and not the scientific sense. In the scientific classification of forms of industry in their successive development, work for buyers-up belongs to a considerable extent to capitalist manufacture, since 1) it is based on hand production and on the existence of many small establishments; 2) it introduces division of labour between these establishments and develops it also within the workshop; 3) it places the merchant at the head of production, as is always the case in manufacture, which presupposes production on an extensive scale, and the wholesale purchase of raw material and marketing of the product; 4) it reduces those who work to the status of wage-workers engaged either in a master’s workshop or in their own homes. These features, as we know, are typical of the scientific conception of manufacture as a special stage in the development of capitalism in industry (see Das Kapital, I, Kapital XII).[16] This form of industry, then, already implies the deep-going rule of capitalism, being the direct predecessor of its last and highest form—large-scale machine industry. Work for the buyer-up is consequently a backward form of capitalism, and in contemporary society this backwardness has the effect of seriously worsening the conditions of the working people, who are exploited by a host of middlemen (the sweating system[9] ), are disunited, are compelled to content themselves with the lowest wages and to work under the most insanitary conditions and for extremely long hours, and—what is most important—under conditions which render public control of production extremely difficult.

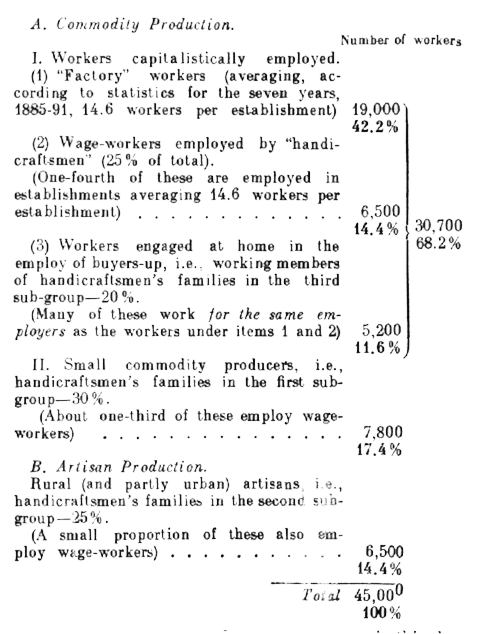

We have now concluded our review of the 1894-95 handicraft census data. This review has fully confirmed the statement made above regarding the utter meaninglessness of the term “handicraft industry,” We have seen that this term has been used to cover the most diverse forms of industry, we might even say: practically every form of industry known to science. And, indeed, the term has been made to include patriarchal artisans who work for private customers using the customers’ own materials and receiving remuneration sometimes in kind, sometimes in cash. Further, it has been made to include representatives of an entirely different form of industry—the small commodity producers who work together in families. It has been made to include owners of capitalist workshops who employ wage-workers, and also these wage-workers themselves, who sometimes number several dozen to an establishment. It has been made to include manufactory owners who possess capital in considerable quantity and command a whole system of detail workshops. It has likewise been made to include workers employed at home for capitalists. In all these subdivisions, both agriculturists and non-agriculturists, peasants and town dwellers have equally been regarded as “handicraftsmen.” The confusion is by no means peculiar to this particular investigation of the Perm handicrafts. Not at all. It is to be met with whenever and wherever anything is said or written about “handicraft” industry. Anybody who is familiar, for example, with the Transactions of the Commission of Inquiry into Handicraft Industry knows that it, too, classes all these categories as handicraftsmen. And it is a favourite method of our Narodnik economists to lump together this endless variety of forms of industry, to call this jumble “handicraft,” “people’s” industry, and—risum teneatis, amici![10] —to contrast this meaningless hodge podge with “capitalism,” with “factory industry.” This admirable method, which testifies to the remarkable profundity and erudition of its initiator, was, if we are not mistaken, “theoretically justified” by Mr. V. V., who on the very first pages of his Essays on Handicraft Industry takes the official figures for the number of “factory” workers in Moscow, Vladimir and other gubernias, compares them with the number of “handicraftsmen,” and finds, of course, that “people’s industry” in Holy Russia is developed to a far greater extent than “capitalism.” But our “authoritative” economist very wisely remains silent on the fact, established time and again by investigators,[11] that the overwhelming majority of these “handicraftsmen” also work for manufacturers. The compilers of the Sketch, faithful to Narodnik prejudices, have used the same method. Although the total annual output of “handicraft” industry in Perm Gubernia amounts to only 5 million rubles,[12] and that of “factory” industry to 30 million rubles, “the number of persons employed in factory industry amounts to 19,000 and in handicraft industry, to 26,000” (p. 364). The classification, you see, is almost touching in its simplicity:

| a) | Factory workers . . . . | 19,000 |

| b) | Handicraftsman . . . . | 26,000 |

| Total: | . . . . . . . . . . . . . . . . . . . . . . . . . . . | 45,000 |

Naturally, such a classification offers endless scope for reflections on the “possibility of a different path for the fatherland”!

But it is not for nothing that we have before us the data of the handicraft household census which investigated the forms of industry. We shall attempt to give a classification that corresponds to the census data (of which the Narodnik classification is a sheer mockery) and to the various forms of industry. We shall apply the percentages revealed by the census for 20,000 workers, to the higher figure of 26,000 derived by the authors from other sources.

We are fully aware that there are errors even in this classification: it does not include factory owners, but does include handicraftsmen who employ dozens of wage-workers; some manufactory owners have been included accidentally, but not specified, while others have not been included, having been discarded as “buyers-up”; it includes urban artisans of one town, but not of eleven other towns, and so on. At any rate, this classification is based on the census data on forms of industry, and the errors mentioned are errors in these data, and not errors of classification.[13] In any case, this classification gives an accurate idea of the real state of affairs, it explains the real social and economic relations of the various participants in industry, and, consequently, their status and their interests—and such an explanation is the supreme task of any scientific economic investigation.

[1] These include two buyers-up (Ponomaryov and Fominsky) who have 217 establishments working for them. Altogether, there are 470 bootmaking establishments working for buyers-up in Kullgur Uyezd. —Lenin

[2] These words are in English in the original. —Ed.

[3] These words are in English in the original. —Ed.

[4] The felt industry in the Arzamas and Semyonov uyezds of Nizhni-Novgorod Gubernia is organised on those lines. See Transactions of the Commission of Inquiry into Handicraft Industry and the Material of the Nizhni-Novgorod Zemstvo Statistical Department. —Lenin

[5] Directory of Factories for 1879. The matting makers working for buyers-up are mostly concentrated in Osa Uyezd. —Lenin

[6] Sketch, p. 157. —Lenin

[7] Per establishment. —Lenin

[8] Sweating system. —Ed.

[9] These words are in English in the original. —Ed.

[10] Restrain your laughter, friends!—Ed.

[11] If nothing more, see Mr. Kharizomenov’s article, “The Importance of Handicraft Industry,” in Yuridichesky Vestnik,[17] 1883, Nos. 11 and 12, which contains a summary of the statistical material then available. —Lenin

[12] Not to mention the curious way in which this figure was arrived at. For instance, the largest component is the flour-milling industry (1,200,000 rubles), arrived at by including the total value of the grain ground by the millers! In the tables and in the description given in the Sketch, only the gross income of 143,000 rubles was taken (see p. 358 and note). The bootmaking industry accounts for 430,000 rubles, a substantial part of which consists of the turnover of the Kungur factory owners ; and so on, and so forth. —Lenin

[13] The objection may be raised that the wage-workers employed by artisan handicraftsmen (20% of the wage-workers employed by handicraftsmen) should be classed under artisan and not commodity production. But here labour-power is itself a commodity, and its purchase and sale is an essential feature of capitalism. —Lenin

[14] The Ministry of Finance Yearbook, Issue I, St. Petersburg, 1869, p 225

[15] The truck system—the system of paying the workers wages in the shape of goods and foodstuffs from the employer’s shop. This system was additional exploitation of the workers, and in Russia, was particularly widespread in the areas where handicraft industry flourished.

[16] Karl Marx, Capital, Vol. I, Moscow, 1958, pp. 336-68.

[17] Yuridichesky Vestnik (The Legal Messenger)—a monthly magazine, bourgeois-liberal in trend, published in Moscow from 1867 to 1892.

| | |

| | | | | | |